FRIES Kunststofftechnik GmbH relies on a four-pillar strategy, divided into the business areas of industrial packaging, catering baskets, industrial baskets and workpiece carriers, as well as technical molded parts. This strategy forms the foundation for the company’s stability, which for 70 years has been developing and producing high-quality plastic products exclusively in Vorarlberg. Strong growth in recent years and a record turnover in the 2024 fiscal year reflect the company’s continuous development. “The number of employees has been steadily increasing since 2019,” mentions Gerhard Bertsch, Managing Director. “Now we have finally reached our capacity limit.”

New Office and Production Building

FRIES Kunststofftechnik GmbH therefore plans to expand its headquarters at the Sulz location. Construction of a new office and production building of nearly 4,500 square meters is scheduled to begin in spring 2026. The overall construction period is estimated at two years.“With this significant expansion, we are reaffirming our commitment to the Sulz location and defying the current economic environment,” explains Bertsch. However, this is not without precautionary measures, for example regarding the supply chain situation. “By expanding the silos and increasing storage capacity, we are becoming more independent and taking preventive steps.”

Environmentally Conscious and Sustainable

Around 5,000 tons of plastic are processed annually at the Sulz plant. All products are environmentally friendly, reusable solutions. In addition, material use is minimized and the share of recycled content is increasing, highlighting FRIES Kunststofftechnik GmbH’s commitment to sustainable and responsible practices. This commitment continues with the new office and production building. The roof will be fully utilized for power generation and equipped with photovoltaic modules with an output of 105 kW/P. The energy generated is connected, among other things, to the industrial heat pump, which is primarily used for cooling. The solar power also provides greater planning security during potential energy crises. “Our investment of 12 million euros in infrastructure also makes an important contribution to regional value creation and secures jobs,” emphasizes Managing Director Gerhard Bertsch, who places particular importance on executing the project through local companies.

Social Area with Terrace

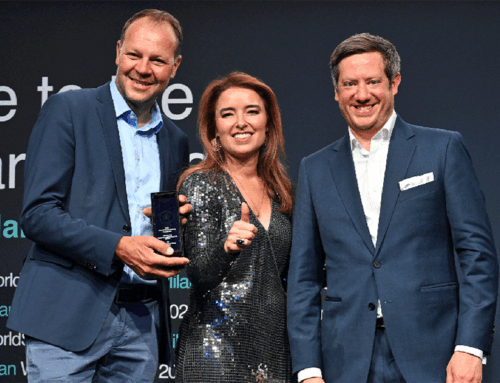

In addition to the injection molding department, the new production hall will also house toolmaking and basket assembly. An automated pallet transport system will simplify delivery, internal handling, and shipping. With a size of 3,000 square meters, there is also sufficient capacity planned for further growth — and the same applies to the offices. “Despite the weakening economy, we are well positioned,” says Bertsch, looking optimistically at the challenges of the coming years. FRIES Kunststofftechnik GmbH also stands out as an employer, as reflected in the accolades the company has received: “Excellent Training Company,” “Vorarlberg’s Most Successful Family Business,” and “Family-Friendly Company.” These awards highlight that employee well-being is a top priority.