Technical moulded parts made of plastic

Bring your ideas into market-ready parts

Competency through experience and know-how

The Fries development specialists have years of experience and know-how in the areas of product development, planning, production, optimisation, inspection as well as testing market-ready products. We provide fast, efficient and competent consultation to find the optimal solution for your product regarding quality, design and costs.

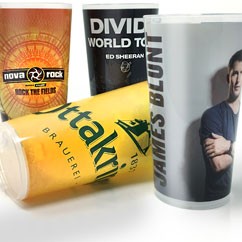

Blow moulding (blow moulding of hollow parts)

This is a procedure in plastic processing to produce hollow bodies made of thermoplastic plastics. The melted plastics (polyethylene, polypropylene) are pressed through the screw conveyor through a nozzle creating a hose-shaped preform (extrusion). This is handed over in the blow mould and adjusted to the inner contours of the shape (blow moulding).

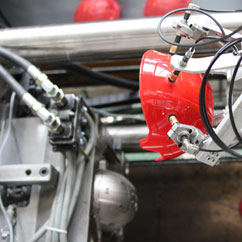

Injection moulding

Injection moulding is one of the oldest procedures for plastic processing. The polymers (plastics) are liquefied with an injection moulding machine and injected into a form (injection moulding tool) under pressure. The plastic is hardened through the cooling in the moulded part and can be removed as a finished piece after opening.

This procedure is suitable for the inexpensive production of large quantities under consideration of the tool costs for the moulded part.