The Variogrid Tech Rack Workpiece Carrier System has won the international Worldstar for Packaging Award 2017. Following the award of the “State Smart Packaging Prize 2016” last November, FRIES is delighted to be recognised with this, the most distinguished award in the packaging industry. The prize was awarded by the World Packaging Organisation WPO as part of the Interpack 2017 event in Dusseldorf.

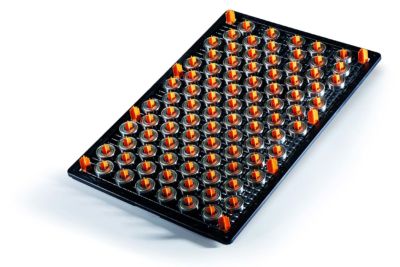

The tech-rack variogrid workpiece carrier system is a true all-rounder in the field of industrial part storage. The variable and modular grid tray represents a further expansion to FRIES’ range of all-in-one workpiece carrier systems, in addition to the techrack industrial racking and the techtray workpiece carrier. Variogrid enables workpiece carrier systems to be configured individually, allowing the workpiece carrier trays to be built to the desired size. This means that trays can be adapted to suit local conditions, such as in the cleaning machine or small load carrier. Rotary stacking bolts can be placed on the grid tray in any combination. This ensures that all sizes are stackable. Tech-rack variogrid offers a wide range of application options for process-optimised machine bench assembly, through to component cleaning, storage, and transportation. A variety of plug-in pins, dividers and accessories serve as finishing touches for the intelligent workpiece carrier system.

The tried-and-tested “tech-rack” industrial racking system and the “techtray” workpiece carrier system also offer high levels of efficiency and significant cost reductions in logistics and cleansing of sensitive metal parts. The systems allow sensitive, valuable components to be cleaned, stored, and transported in a secure and straightforward manner. Best of all, everything is achieved with a single workpiece carrier, with no need to remove and repack everything.

In sensitive sectors such as metallurgy, optics, medical technology, robotics, microelectronics or precision engineering, component cleaning is a central aspect of all production and assembly processes. In this process, customised workpiece carriers are used for each part, requiring workpieces to be fixed in a particular position at particular location in order to achieve optimum cleanliness.